Fabricated wire mesh is often used for burners and heater elements; flame guards and spark arrestors; vent screens; machinery and equipment safety guards and cages; screen sections for sizing and sifting equipment; shielding and sound control components.

The most important part of the strainer or filter is the screen, which guards an orifice or protects moving parts. One particle of scale, dirt, or other entrainment can cause serious damage to highly engineered, expensive equipment. To prevent equipment damage and protect against contamination, strainer screens must be designed of durable, corrosion-resistant materials with the specific application in mind. Cleveland Wirecloth individualizes strainers to customers’ design or we design a strainer to fit specific requirements. Our modern production facilities include electronic welding, soldering, stamping, rolling, folding, seaming, brazing, with particular attention being given to the finish desired.

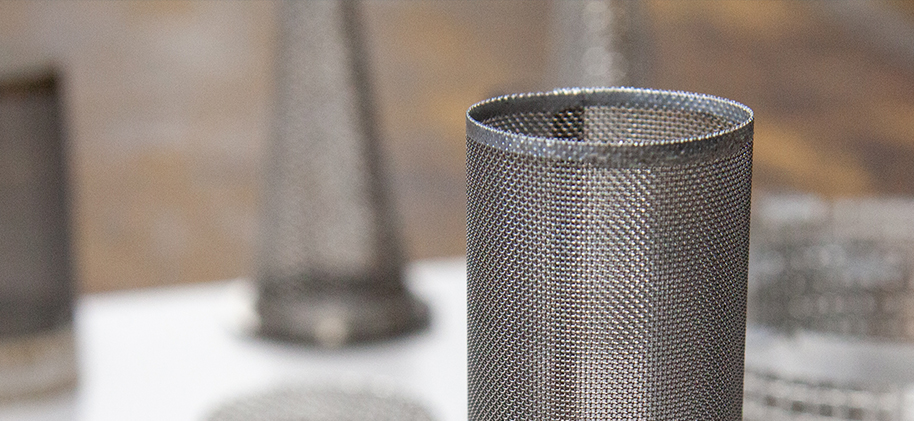

Woven wire is the most popular material used in the manufacture of modern strainer screens. This is partly due to its inherent characteristics — high percentage of open area and roundness — which favor high flow and are ideal for flow patterns. Other reasons for woven wire popularity include its high strength and its ability to withstand extreme temperature variations, corrosive environments and vibration.

Woven screens find their greatest use in low and medium-pressure applications and typically range from 60-400 mesh. In high-pressure service, the fine mesh screen may be supported by a coarse backing screen. Plain weave screens ranging from .0008″ openings upward represent the bulk of strainer applications. For high pressures or heavy loads, twilled weaves are recommended.

- Woven Strainer Screen Metals: Popular metals for woven wire strainer screens are nickel, inconel, monel and stainless steel. Other materials available include steel, galvanized, copper, brass, bronze, aluminum and others.

- Strainer Shapes: Various strainer shapes include cylinders with closed and open ends, conical, frustrated cone, flat disc, semi-circular, dome shape, flat and flat irregular. Cylindrical strainer screens with one end closed are a popular shape. Closed end design can be flat, rounded or chisel pointed and constructed of solid metal or screen.

- Single Screen Strainers: For general service, simple straining problems, light and medium grades of materials with from 40% to 50% open area are recommended. This application is good for moderate-pressure applications.

- Multi-Screen Strainers: For complex straining applications, a combination facing screen for separation and backing screen for support is used.