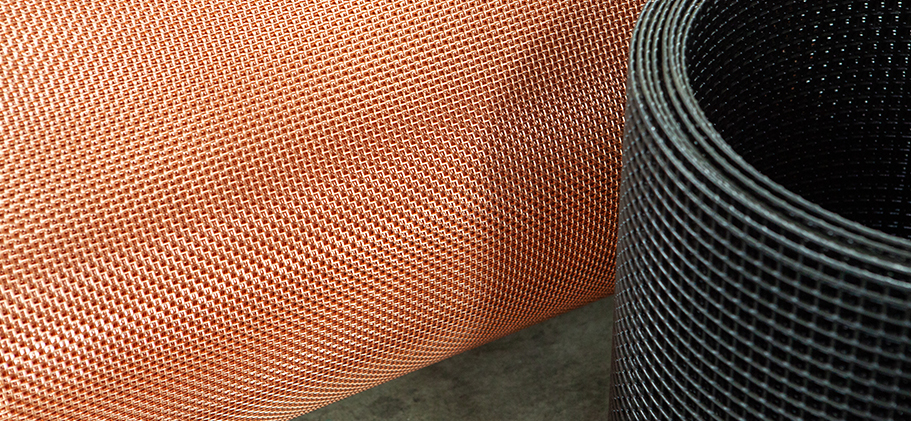

Need help in determining your wire cloth needs? Here are some important terms to know when specifying or purchasing wire cloth.

- ABSOLUTE FILTER RATING: A term used to specify Dutch Weave filter cloth. A measurement of the largest hard-spherical particle that can pass through a specific screen under certain test conditions, usually a bubble point test.

- BOLTING CLOTH: A group of specifications that calls for smaller wire diameters, producing a relatively light mesh. Bolting cloth is principally used in sifting and screen printing; however, its relatively high percentage of open area makes it desirable in other applications.

- CALENDARED WIRE CLOTH: A wire cloth that has been passed through a pair of heavy rolls to reduce its thickness or flatten the intersections of the wires and provide a smooth surface. The term “rolled” is also used.

- COATINGS: The wire used for weaving wire cloth can be coated, plated, or finished in some other way before weaving. Wire cloth may also be coated after weaving (Also see Surface Condition).

- CRIMP: Corrugations in wires to lock them in place.

- DOUBLE CRIMP: Corrugations in both warp and shute wires to lock wires in position.

- DUPLEX WEAVE: Similar to a Plain Dutch Weave, except that two warp wires are used rather than one.

- DUTCH TWILL WEAVE: Similar to a Plain Dutch except woven in the Twill Style. Each wire passes over two wires and then under two wires, still utilizing a smaller diameter shute wire, allowing an even tighter weave and finer filtration than Plain Dutch Weave.

- FLAT TOP: Wire cloth with deep crimps, as in lock crimp, except that all crimps are on the underside of the cloth, leaving the top surface all in one plane. (Also referred to as Smooth Top.)

- FILTER CLOTH: A special type of wire cloth woven with a greater number of wires in one direction than the other and utilizing two different wire diameters (also referred to as Dutch Weave).

- INTERMEDIATE CRIMP: Extra crimps in warp and shute wires between intersections. Generally used in wide-mesh, light-wire combinations to stiffen fabric and ensure accurate mesh.

- LOCK CRIMP: Pre-crimped wire cloth with deep crimps at points of intersection to lock the wires securely in place.

- MARKET GRADE: An older term referring to an arbitrary group of wire cloth specifications — usually lower-quality imported goods — designated for general-purpose, low-technology applications where consistent dimensions and material traceability are not critical.

- MESH: The number of wires per linear inch or 25.4 millimeters, counted from the center of any wire to exactly one inch or 25.4 millimeters distant — including the fractional distances between wires thereof.

- MICRON: A unit of length in the metric system. One micron is equivalent to 0.00003937 of one inch (.001 mm).

- OFF COUNT: A mesh with a greater number of wires per inch in one direction — usually the warp direction — than the other. Sometimes referred to as rectangular mesh (100×90, 50×40).

- OPEN AREA: Expressed as a percent that indicates the proportion of a total screen area that is open space.

- OPENING: The dimension between two parallel adjacent wires, usually in decimal parts of an inch. The theoretical width of an opening is a direct function of the mesh count and wire diameter.

- PERCENT OPEN AREA: The ratio of the area of the openings to the total area expressed as a percentage.

- PLAIN DUTCH WEAVE: Woven in a plain, over-and-under pattern. A thinner, smaller diameter shute wire is used; these are driven very close together, creating a very tight weave. Dutch Weaves do not have a straight-through, clear opening as do most Plain Weave styles. Instead, the weave style creates a tortuous path through which very fine filtration and particle retention can be achieved. Dutch Weaves may be specified by “mesh count” or “absolute filter rating.”

- PLAIN WEAVE, PLAIN SQUARE WEAVE: Wire cloth in which each warp wire and each shute wire passed over and under the next adjacent wire in both directions.

- PRECRIMP: Wire cloth is woven with both the warp and shute wires crimped before weaving.

- REVERSE DUTCH WEAVE: The same weave as Plain Dutch except the warp and shute wires are reversed; i.e., the warp wires have a smaller diameter than the shute wires. The larger shute wires are woven closer together than would usually be seen in a Plain Dutch Weave.

- SELVAGE: The edge or border of wire cloth, finished off to prevent unraveling. Where a “selvage edge” instead of a raw or cut edge is a specific requirement, it should be specified, as well as the type (looped, folded, welded).

- SHUTE WIRES: The wires running the short way of, or across the width of, the cloth as woven. (Also referred to as the shoot, fill, or weft wires.)

- SIEVE CLOTH: Wire cloth specified by opening width based approximately on the fourth root of 2 Series. Sieve cloth is generally used for the determination of particle size as opposed to the separation of particles.

- SMOOTH TOP: Wire cloth with deep crimps, as in lock crimp, except that all crimps are on the underside of the cloth, leaving the top surface all in one plane. (Also referred to as Flat Top.)

- SPACE CLOTH: Wire cloth that is designated by the width of the open spaces between the inside faces of adjacent parallel wires, expressed in inches or the metric equivalent.

- SQUARE MESH: Wire cloth has the same number of wires and wire diameters in both the warp and shute.

- SQUARE WEAVE: see “Plain Weave.”

- SURFACE CONDITION: Woven wire cloth may be covered with a film of oil or other lubricant due to the manufacturing process. The wire may show traces of products used in the drawing process. Depending on the material, there may be traces of corrosion.

- TWILL DUTCH WEAVE: Similar to Plain Dutch except woven in the twill style. Each wire passes over two wires and then under two wires, still utilizing a smaller-diameter shute wire, allowing an even tighter weave and finer filtration than Plain Dutch Weave.

- TWILL WEAVE: A pattern where each wire goes alternately over two wires and then under two successive wires. Herringbone Twill is a special type in which the direction of the twilled weave is reversed at regular intervals to produce a striped or herringbone effect.

- TWIN WARP: see “Duplex Weave.”

- WARP WIRES: The wires that run the long way of the cloth as it is woven.

- WEFT WIRES: see “Shute Wires”

- WEIGHT PER UNIT AREA: The weight per square foot for wire cloth can be approximated (without consideration for crimp).

- WIDTH OPENING: The distance between two parallel adjacent warp or shute wires, measured in the projected plain.

- WIRE DIAMETER: The measurement of the thickness of an individual wire.